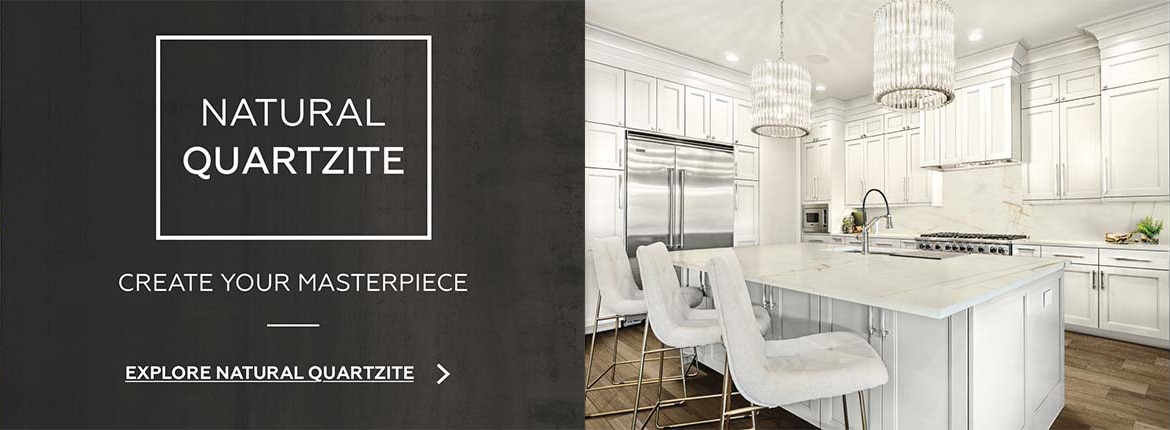

What’s the perfect kitchen countertop? What makes the best bathroom vanity? Can’t decide between quartzite vs. granite or marble vs. quartz countertop? Shopping for a countertop comes with a lot of questions.

Our extensive selection includes every option, from the finest natural stone to enduring ONE Quartz to our award-winning Panoramic Porcelain.